GE Pro-Face Xycom GP675-TC11 Panel Industrial HMI Solution

Dimensions:346W x 272H x 81D mm Display Type:TFT Color LCD Resolution:800 x 600 dots Operating Voltage:AC 85-132V 50/60Hz, DC 24V +/-20% Touch Panel:Resistive Film, 40 x 30 keys, 1 or 2-point touch Memory:2 MB Application Memory, Additional Backup Memory Interfaces:Printer Output, Auxiliary I/O, Tool Connector, Serial Port (2400 to 38400 bps) Weight:<3.8 kg before packaging Engineered for durability and reliability, the GE ProFace Xycom GP675-TC11 is built to withstand harsh industrial conditions. Its robust construction ensures long-lasting performance even in challenging environments.

The unit features a user-friendly touch panel interface that supports multiple languages, including ASCII, Chinese, and Korean, allowing for seamless communication across diverse international workforces. With its expandable character size options, from 1x to 8x, the GP675-TC11 offers customizable text sizes to suit various display needs, enhancing readability and user interaction.

Equipped with vibration resistance capabilities from 10 to 25 Hz and high noise immunity up to 1200Vp-p, this HMI is designed to maintain optimal performance in noisy industrial settings.

For easy integration into existing systems, the GP675-TC11 includes comprehensive documentation and support from AX Control, ensuring a smooth setup process and access to technical assistance when needed.

The GE GP675-TC11 Panel is a high-performance Human-Machine Interface (HMI) solution designed for industrial control applications, offering a 12.1-inch TFT color LCD with a resolution of 800 x 600 dots, ensuring clear and detailed visual information.

Precise Manufacturing Process

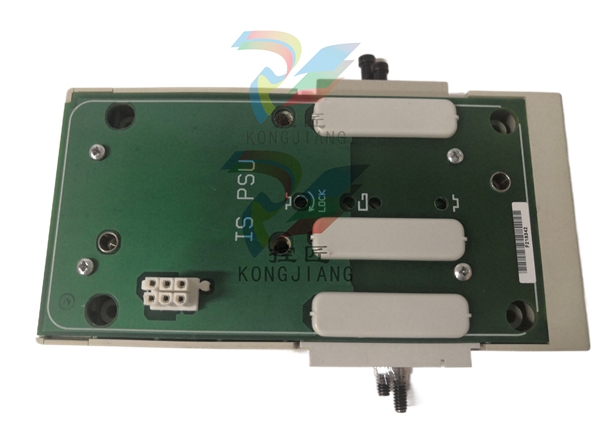

Circuit Board Manufacturing: Adopting advanced multi-layer printed circuit board (PCB) technology, the circuit layout is carefully optimised using professional circuit design software at the design stage, with full consideration given to factors such as electrical performance, heat dissipation performance and electromagnetic compatibility.

Through the optimisation of the line layout, the line resistance and inductance are reduced to improve the efficiency of signal transmission and at the same time reduce signal interference. In the manufacturing process, high-precision etching process is used to control the line width and spacing precision at the micron level to ensure the accuracy and stability of signal transmission.

For the power circuit section, special copper foil thickening is used to withstand the passage of high current. In the soldering section, high-precision surface mount technology (SMT) and wave soldering technology are used to accurately attach electronic components to the circuit boards by utilising automated soldering equipment and strictly controlling parameters such as soldering temperature, time and pressure. Each solder joint undergoes strict quality inspection, and X-ray inspection equipment is used to check whether there are defects such as false soldering and voids inside the solder joints to ensure the reliability of the circuit board's electrical connection.

For high-speed signal circuits, special impedance matching design and circuit processing technology are used to reduce signal reflection and attenuation, ensuring high-speed stability of data transmission.