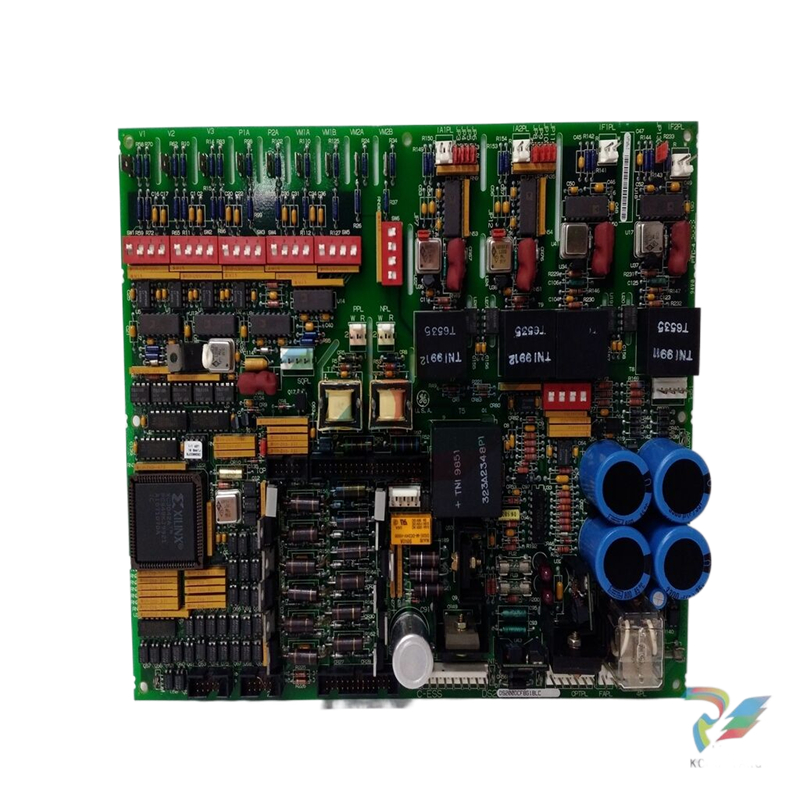

GE IS415UCVHH1AB Advanced VME Control Board for Mark VIe DCS

Number of Faceplate Alarm LEDs:5 Manufacturer:General Electric Industrial Systems Weight:Approximately 3lbs VME Control Board Compatibility:Mark VIe Distributed Control System series Redundancy Support:Simplex, Dual, Triple Controller Components:RAM slot, 128MB Compact Flash Disk, Heatsinks, CMOS Battery USB Ports:2 Ethernet Ports:2 COM Ports:2 with corresponding LEDs Dimensions:Not specified Weight:Not specified Experience unparalleled reliability and efficiency with the GE IS415UCVHH1AB, engineered to seamlessly integrate into the Mark VIe DCS ecosystem.

Featuring 5 faceplate alarm LEDs, this control board ensures real-time monitoring and quick response to operational anomalies. Built with robust components akin to those found in personal computers, including RAM slots, a 128MB Compact Flash Disk, heatsinks, and a CMOS battery, this board ensures optimal performance under demanding conditions.

The IS415UCVHH1AB is not just a control board t a solution for complex industrial automation challenges, providing a solid foundation for turbine control and management. Only trained personnel should handle this equipment due to its critical role in maintaining system integrity. AX Control stocks a vast array of genuine GE parts, ensuring swift delivery upon order.

For those looking to maximize their investment, we offer bulk purchase options and repair services. Don settle for anything less than top-tier performance pgrade to the GE IS415UCVHH1AB today. The GE IS415UCVHH1AB is an advanced VME control board specifically designed for complex industrial automation systems, ensuring reliable operation in demanding environments.

Cutting-edge technology features

(A) Powerful computing and processing capabilities

GE IS415UCVHH1AB control board is equipped with a high-performance processor core, with excellent computing performance. Its computing speed can reach billions of floating-point operations per second, and it can quickly process a large amount of complex data from all kinds of sensors, actuators and other devices in the Mark VIe DCS system. The control system of a large power station involves real-time monitoring and control of many parameters, such as generator voltage, current and frequency, turbine speed, temperature and pressure. The control board can quickly analyse, calculate and process these data, adjust the control strategy in time, and ensure the stable operation of power generation equipment and efficient power generation.

At the same time, it can also carry out real-time processing of equipment operation status data to achieve early warning of equipment failure and avoid production interruption due to equipment failure. For example, through the continuous monitoring and analysis of generator winding temperature, vibration and other data, potential equipment problems can be found in advance, providing sufficient time for maintenance personnel to carry out overhaul and guaranteeing the reliability of power supply.

(ii) Efficient VME bus communication

As a VME control board, IS415UCVHH1AB excels in VME bus communication. It supports the high-speed VMEbus protocol with a data transfer rate of up to [X] Mbps, which ensures that data interaction with other devices under the VMEbus architecture can be carried out quickly and accurately. In industrial automation systems, different devices need to exchange data frequently, such as issuing control commands and providing feedback on device status information.

Through the VME bus, this control board can communicate efficiently with distributed I/O modules, communication modules and other control boards to build a stable and reliable control system network. In a large-scale chemical production plant, the IS415UCVHH1AB control board is connected to the I/O modules corresponding to temperature, pressure, flow and other sensors in the field through the VME bus, which collects all kinds of parameters in the production process in real time and transmits the control instructions to the actuators quickly to realise the precise control of the chemical production process. At the same time, it can also work with the communication module to upload production data to the superior monitoring system, providing data support for production management.