General Electric DS200TCCAG1AHB High-Performance Control Module

Operating Voltage:120V AC / 24V DC Operating Temperature:-20"C to +70"C Power Consumption:15W Communication Interface:RS-485, Modbus-RTU Load Capacity:Up to 10A per channel Relay Type:Solid State Relay Dimensions:178.2mm x 95.3mm x 45.0mm Weight:0.5kg Engineered with state-of-the-art semiconductor technology, the DS200TCCAG1AHB control module ensures robust performance in harsh industrial environments.

Its advanced design allows for precise control over processes, optimizing energy consumption and enhancing operational efficiency. Featuring a compact yet rugged construction, this module is built to withstand extreme temperatures and vibrations, making it ideal for applications in manufacturing, energy, and process industries where reliability is paramount.

With a high-speed RS-485 communication interface, the DS200TCCAG1AHB facilitates seamless data exchange with other components in the system, ensuring smooth coordination and control.

It supports a variety of input types, including digital signals, allowing for versatile integration into existing automation networks. Equipped with high-current relay outputs, this control module provides a safe and efficient means to control motors, solenoids, and other power-consuming devices.

The 24VDC, 5A rating ensures compatibility with a wide range of industrial equipment, enhancing system flexibility. Designed with user-friendliness in mind, the DS200TCCAG1AHB includes intuitive diagnostic features and easy-to-read LED indicators, facilitating quick troubleshooting and maintenance. Its CE and UL certifications guarantee compliance with international safety standards, ensuring peace of mind for users worldwide. The General Electric DS200TCCAG1AHB is a high-performance control module designed for advanced industrial applications, offering robust reliability and precise control in harsh environments.

Quality Assurance

(A) Precision manufacturing process

Circuit Board Manufacturing: Adopting advanced multi-layer printed circuit board (PCB) technology, through the optimised line layout and high-precision etching process, the line width and spacing precision is controlled at the micron level, which effectively reduces the signal interference and improves the stability of the module's electrical performance.

During the circuit board welding process, high-precision surface mount technology (SMT) is used to accurately mount electronic components on the circuit board. Using automated welding equipment, the welding temperature, time and pressure and other parameters are strictly controlled, and each solder joint is strictly inspected. X-ray inspection equipment is used to check whether there are defects such as false soldering and voids inside the solder joints to ensure the reliability of the circuit board's electrical connection. For high-speed signal lines, special impedance matching design and line processing technology are used to reduce signal reflection and attenuation to ensure the accuracy and stability of data transmission.

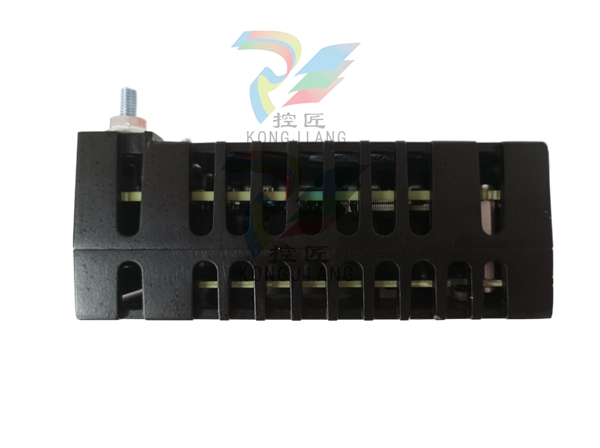

Module assembly: During the assembly of DS200TCCAG1AHB modules, high-precision automated equipment is used to strictly control the assembly precision of each component. The dimensional accuracy and contact performance of key components such as communication interfaces, input/output interfaces, etc. are strictly controlled to ensure the stability and signal transmission quality when connecting with external devices.

The module shell is made of high-strength, fire-resistant, anti-electromagnetic interference engineering plastics, and undergoes a precision injection moulding process to ensure the dimensional accuracy and mechanical strength of the shell. In the manufacturing process of the shell, the design and manufacture of the mould is strictly managed to ensure that all parts of the shell can be accurately docked to provide good protection for the internal electronic components, and effectively resist the physical damage and electromagnetic interference in the industrial environment.